Rod Mills Grinding Versus Ball

2022-02-23T22:02:27+00:00

What are the differences between ball mill and rod mill?

2021 4 2 This kind of rod mill can be used for wet grinding and dry grinding "A rod mill is recommended if we want to properly grind large grains, because the ball mill will not attack them as well as rod mills will" ① End and side discharge rod millAs grinding equipments, ball mills and rod mills are both high efficiency grinding equipments Their common points are: 1 They have the same function, they are all used to grind materials, so that the materials can reach the state of powder; 2 The shape of ball mills and rod mills Ball Mills vs Rod Mills How To Choose Ball Mill or Rod Mill2021 4 1 When the mill is rotated without feed or with very fine feed, the rods are in parallel alignment and in contact with one another for their full length New feed entering at one end of the mill causes the rod charge to spread at that end This produces a Ball Mills vs Rod Mills Metallurgist Mineral Processing

difference between ball mill and rod mill grinding

Ball mills are so termed in the trade when using balls as a grinding media in andthe difference of screen sizing as produced by mills grinding a stabilized mill load g 5 with enlarged collar on the rod midway between the rod and terminals mechanism and equipment to be inclined or tilted as a unit and with the millrod mills grinding versus ball This page is provide professional rod mills grinding versus ball information for you, we have livechat to answer you rod mills grinding versus ball question here rod mill crusher vs ball mill crushercrusher mining processrod mill vs ball mill Mining Quarry PlantRequest PDF Flow of materials in rod mills as compared to ball mills in dry systems The rod mill product is characterized by its narrow size distribution if it is compared with that of a ball Flow of materials in rod mills as compared to ball mills in

Rod mills, how they function Mine

2012 11 26 Rod mills are very similar to ball mills, except they use long rods for grinding media The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, 2020 12 16 Rod mill A rotating drum causes friction and attrition between steel rods and ore particles [citation needed] But note that the term 'rod mill' is also used as a synonym for a slitting mill, which makes rods of iron or other metal Rod mills are less common than ball mills for grinding mineralsMill (grinding) WikipediaAlternatively, ball mills are closed systems and do not offer these advantages Nevertheless, ball mills can be a more appropriate choice for grinding larger sized material starting at 1/4 ” or larger It should be noted that ball mills are much larger than Attritors and therefore require a special foundationHigh Energy Ball Milling Union Process

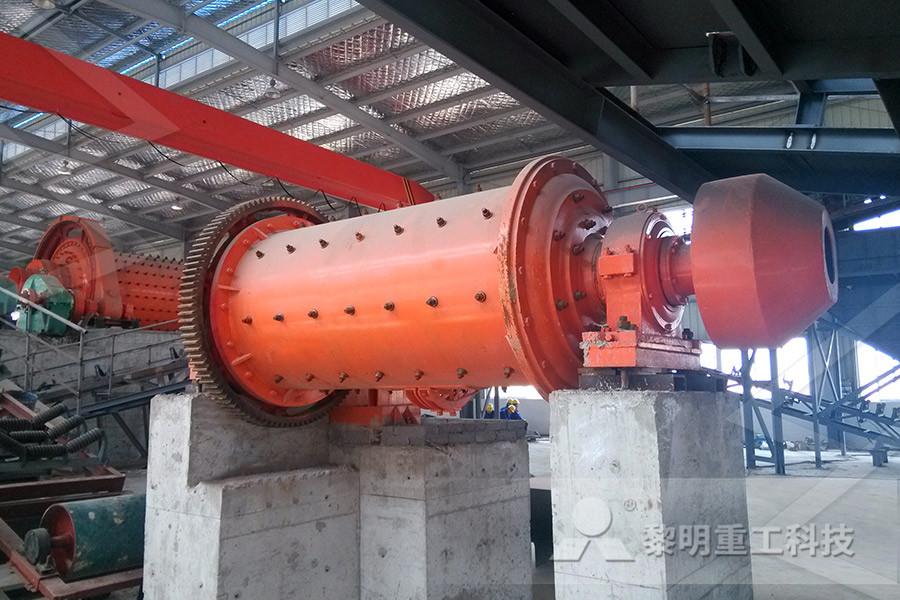

Rod Mills for coarse grinding

Rod Mills are particularly useful, if you run a low tonnage operation and are looking for coarse product Our Rod Mills are available in multiple diameters to fit the needs of your operation Grinding, primarily by attrition, Rod Mills require comparatively low levels 2020 3 27 Rod mill is a type of grinding mill whose grinding media is steel bar, while ball mill is steel ball 1 Rod mill are usually applied to grinding the wsn ore and rare metal in the reselection or magneticoredressing plant in order to avoid the damage caused by the over crushing 2 In the two stage grinding process, if it requires grinding the ore from 206mm to 13mm in the first stage, rod Comparison between Rod Mill and Ball Mill ore 2020 4 24 Ball mill and Rod mill is a tool used in modern mineral processing, coal chemical industry, sand making and other industries to grind ore into powder and then used in smelting industry to smelt gold, steel, etc Coal chemical industry coal water History of the Ball Mill and Rod Mill Grinding Balls

Flow of materials in rod mills as compared to ball mills

The rod mill product is characterized by its narrow size distribution if it is compared with that of a ball mill operating under the same conditions in open circuit This is partly due to the As such, when the product is sticky, rod mills are preferred over ball mills Rod mills have an industrial yield that is less than that of a ball mill, which explains the fact that balls have a much larger grinding surface than rods The power needed to operate a rod mill could exceed 30% of the power used in a ball millRod Mill an overview ScienceDirect TopicsJaw and gyratory crushers are used for initial size reduction to convert big rocks into small stones This is generally followed by a cone crusher A combination of rod mill and ball mills are then used if the ore must be ground below 325 mesh (45 μm) Instead of grinding the ore dry, slurry is used as feed for rod or ball mills, to avoid dustingGrinding Circuit an overview ScienceDirect Topics

L

2003 3 5 FIG 2 Plot of cumulative percentage of limestone finer than each sieve size versus grinding time in (a) the ball mill and (b) the rod mill 2 in Fig 4a, the initial rates of formation (given as cumulative percentage of material finer than any stated size per minute) of limestone and quartz are plotted semilogarithmically as a function of2009 7 30 Figure 82 Media motion in the tumbling mill 81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between theTECHNICAL NOTES 8 GRINDING R P KingThis is the most common mode used during operation of rod mills, ball mills with central unloading and pipe mills in the case of wet and dry grinding of noncorrosive materials Mixed operating mode is illustrated in the figure b, where the dotted line shows the position of the grinding balls in flight along the trajectory and solid lines – balls THE MODE OF BALL MILL OPERATION

Rod Mills Mineral Processing Metallurgy

2021 4 4 Metallurgical ContentRod Mill Capacity and Sizing TableROD MILL SPECIFICATIONSROD MILL CAPACITIESROD MILL General ArrangementDimensionsPERIPHERAL DISCHARGE ROD MILLSWet Grinding ROD MILLINGDry ROD MILL GrindingCENTER PERIPHERAL DISCHARGE ROD MILL Rod Mill Working Principle ComponentsRod Mill Grinding The Steel Head Rod Mill (sometimes call a bar mill2020 12 21 * Mills come along with a control panel and has an automatic lubrication unit * Ball/Rod Mills can be specially designed for wet or dry grinding Compared to similar equipment, Ersel Ball/Rod Mills provided low energy consumption and high efficiency, as a result of our improvements based on our RD studies and process experienceERSEL Ağır Makine San ve Tic AŞBall mill and rod mill are the common grinding equipment widely used in the mineral processing plant They are similar in shape and grinding principle, but also different in structure, performance and application Here are seven differences between ball mill and rod mill to tell you how to choose the ball mill and rod mill7 Differences Between Ball Mill and Rod Mill Xinhai

difference between ball mill and rod mill grinding

Ball mills are so termed in the trade when using balls as a grinding media in andthe difference of screen sizing as produced by mills grinding a stabilized mill load g 5 with enlarged collar on the rod midway between the rod and terminals mechanism and equipment to be inclined or tilted as a unit and with the mill2021 3 30 Density, if you recall is the ratio of ore to water and is measured as a percent of solids in the water It will control the grind in two ways It affects retention time and helps distribute the ore throughthe mill so each piece of rock will come in contact with the surface of the rods To maintain a proper balance between these two is critical What water does is kind of provide a mode of Ball Rod Mill Density How Water Impacts GrindingRod mills commonly use steel rods with a diameter of 50100mm as the grinding medium, while ball mills use steel balls as the grinding medium The difference in the grinding body is the main How to Choose a Ball Mill or a Rod Mill? by

What's the Difference Between SAG Mill and Ball Mill

Grinding ratio can reach 4000 ~ 5000, more than ten times higher than ball, rod mill Application Autogenous mills are common in the primary processing unit for the major large grinding circuits in the mining field, separates out some precious metals, like gold, silver Ball 2020 3 23 Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology FLSMIDTH 2 Introduction Around 110 years ago a Danish engineer, M Davidsen, patented a pioneering invention in France which involved a tube mill with a charge of steel balls or flintCement grinding Vertical roller mills versus ball millsMills » Products » CEMTEC Cement and Mining Technology The designs and sizes of CEMTEC's mills and grinding plants depend on the raw Double chamber ball mills for the cement industry come in various designs: Vertical roller mills are suitable for plant capacities between 2 tph and 40 tph,roller mill vs ball mill in mine grinding plant

Breakage of Steel Grinding Rods in Rod Mill Grinding

When rod mill user’s steel grinding rods are broken, they could find out the reasons from the following aspects (for reference only): 1 The strength and hardness of steel grinding rod is not up to standard; 2 Corrosion of steel grinding rod caused by too high content of sulfur and phosphorus in rod mill; 3 Steel grinding rod wear too fine and rod RoM Ball mills, like SAG mills, utilise coarse rocks in the RoM feed as grinding media but with 25 – 40% steel balls added, which is advantageous when the coarse fraction in the RoM feed is RoM BALL MILLS A COMPARISON WITH AG/SAG MILLINGAs a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for grinding Metallic and Nonmetallic Minerals Grinding by Ball Mill