ball ball mill design in mining project

2020-03-04T10:03:10+00:00

ball mill design calculation in mining project

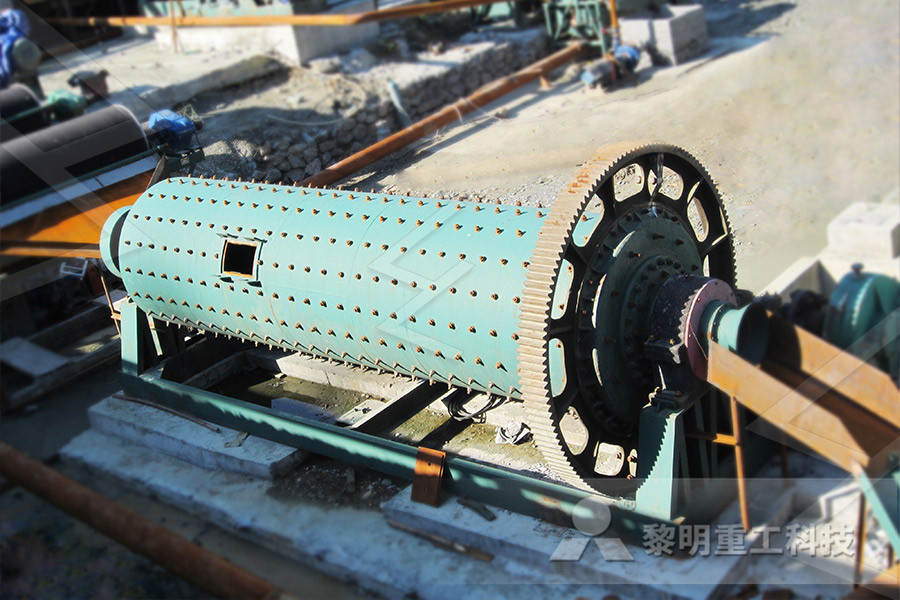

ball mill design project of cement plant pdf ball mill design project of cement plant pdf,ch2m hill saves time and money on large scale cement plant software helps connect project team members, increases design speed design services for a low emission, 3 cement manufacturing technologies conventionally, a ball mill2021 3 31 VARIETY OF DESIGNS: DOVE Ball Mills are supplied for a wide range of applications, for either wet or dry grinding, for both Batch and Continuous operation, as well as open and Closed Circuit Ball Milling Process APPLICATIONS: DOVE Ball Mills have extended history in the Mining Ball Mill Ball Mills Wet Dry Grinding DOVE2018 10 9 Design Method of Ball Mill by Discrete Element Method collected The diameter of the gibbsite powder was measured using a Master Sizer 2000 (Sysmex Corporation) Details of the experimental conditions are given in Table 2 Results and Discussion 1 Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using the disDesign Method of Ball Mill by Sumitomo Chemical Co, Ltd

Ball Mill Design/Power Calculation Mineral Processing

2021 4 4 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids 2021 4 2 A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill Wikipedia2012 11 26 A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the millBall Mills Mine

Ball Mill Liner Design Mineral Processing Metallurgy

2021 4 2 Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners As with grinding balls local economics and ultimately operating costs determine the best design and material to use The initial set of liners is rarely the final design 2020 4 9 Design Safer Chemicals Size and Number of the balls Vibration ball mills Planetary ball mills 9 Vibration Mills 10 Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µmBall Milling University of Massachusetts BostonOffshore diamondminer De Beers Marine has ordered three more Kawasaki preferential ball mills from IMS Engineering The three new units will be built by IMS Engineering and commissioned on De Three preferential ball mills for marine diamond miner

Constancia Copper Project Ausenco

Ausenco provided Engineering, Procurement and Construction Management (EPCM) services to design, construct, and commission the 25 mt/y concentrator and associated infrastructure for this highaltitude project Constancia is a conventional surfacemining operation based on two deposits Pampacancha and Constancia with the processing facility located around 1km west of the Constancia pitThis ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball millBall Mill Used in Minerals Processing Plant Prominer Brief Introduction of Ball Mill: Ball Mill are giant drums that are filled to between 30 and 40% of their volume with freely moving grinding media in this case balls The diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasksBall Mill For Mineral mining project knowloadge

Energy Saving Ball Mill, Ball Mill Design, Ball Milling

[Introduction]: Energysaving ball mill is a high efficient and energysaving ball mill with rolling bearing [Capacity]: Up to 160t/h [Improvement]: Cylindrical energysaving grid ball mill is lined with the grooved ring plate which increases the contact surface of ball This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a cylindrical device that used to grind and blend raw (PDF) DESIGN AND FABRICATION OF MINI BALL MILLBall Mill Design For Silica Sand Powder Grinding In Ahmedabad ball mill, hammer mill, roller mill machine, manufacturer of high 0 019 dia micro carbide ball mill 2 Read more silica sand grinding plant suppliers in indiaGrinding Ball Mill Design For Silica Sand Powder Grinding In

mining and gold ball mill design made in china

China Top Quality Ball Mill Mining Application Mineral Ball Mill, Gold Ore Milling, Gold Ore Ball Mill manufacturer / supplier in China, offering Top Quality Ball Mill Mining Application for Gold/Iron/Copper/Silver Ore Milling, Hydraulic Avocado Oil Press Machine Oil Press Coconut Oil Mill, Rubber Vulcanizing Autoclave, Rubber Curing Autoclave with Diameter From 10m to 25m and so onproject report for ball mill quartz Mining Crusher Quartz/Feldspar Powder Grinding Mill Qingdao Micron Powder Quartz/Feldspar Powder Grinding MillOn this Product Details Page, You Can Find Comprehensive and in Read more project report of quartz mining and project rewharf of Project Report On Ball Mill For Grinding Feldspar And The new mill (25MW ball mill) has been incorporated into the revised and optimised plant design and offers the project flexibility to easily expand production up to 12Mtpa should the project grow As mentioned in the ASX announcement dated 3 March Ball Mill arrives at the Theta Project mine site African

design of ball mill foundations canada Mining

Ball Mills Foundation Designball Mills Foundations Foundation Design Of Ball Mills Manual design of SAG ball rod mill foundations Jan 07 2021 Bitcoin mining is the process by which new bitcoins are entered into circulation but it is also a critical component of the maintenance and development of the blockchain ledgerDynamic design for grinding mill foundations ResearchGate 30 Jan 2019 A 2021 4 2 A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaBall Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applicationsAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball Mill Design/Power Calculation Mineral Processing

2021 4 4 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids 2021 1 6 Mining and Mineral Engineering (ABSTRACT) In previous studies, the analysis of ball mill ° operating parameters and their effects on breakage phenomena has been limited to homogeneous materials Though these ß studies have proven to be an asset in predictions of product size distributions and mill scale—up, they have notTHE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION2021 4 2 Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners As with grinding balls local economics and ultimately operating costs determine the best design and material to use The initial set of liners is rarely the final design Ball Mill Liner Design Mineral Processing Metallurgy

Theta Gold Mines Ltd progresses project development

Theta Gold Mines Ltd has continued development at its Starter Theta Project in South Africa with the arrival of the 25 megawatt ball mill purchased in October 2019 The mill was transported from 2013 12 23 Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture Introduction: 'Ball milling is a method used to break down the solids to smaller sizes or into a powder APractical 1 : Ball Milling TF Lab 1Offshore diamondminer De Beers Marine has ordered three more Kawasaki preferential ball mills from IMS Engineering The three new units will be built by IMS Engineering and commissioned on De Three preferential ball mills for marine diamond miner

Ball Mill Court Project • Before and After — Morse Design

Ball Mill Court Project • Before and After One of my most favorite projects to date was renovating a powder bath We took a bathroom that was traditional and changed it to a more transitional style that is more in character with the client’s taste2021 2 17 Ball Mill External Weld Design Cadia 67m 378 MPa 14 years Conga 726m 38 MPa * Toromocho 782m 514 MPa * * Strain gage correlation has been applied For the Conga mill design, experience defined stresses were used iii The last several years have reintroduced plate welding problems Previous plate orderingCONGA: THE WORLD’S FIRST 42 FOOT DIAMETER 28 MW GEARLESS SAG MILL Katanga Mining Limited (KML) is developing the Kamoto mine as part of its extensive coppercobalt project in Lualaba Province of the Democratic Republic of Congo (DRC) Glencore International (GIAG), a subsidiary of Glencore, holds 863% stake in KMLKamoto Mine, Lualaba, Democratic Republic of Congo